Ever felt like building a house takes forever? You are not wrong. The average single home in the US can take an average of seven months to build. But what if you could print your home in a matter of hours and at a fraction of the cost? Welcome to the revolutionary world of 3D printing, a technology stepping straight out of sci-fi and into the construction industry. This is not just a gimmick; it is a total transformation of how we think about the construction process and 3D printed house designs.

This technology is reshaping the housing industry and grabbing serious attention across Europe and the US. It involves using large-scale 3D printers to create a three-dimensional object by solidifying materials based on a digital file. Instead of just being used for rapid prototyping, we are now building actual, livable homes. These technology-driven houses are not only unique but also offer incredible new possibilities for future designs.

So, what is all the buzz about? This article covers the most incredible 3D printed house designs out there. We will explore the benefits, break down how these homes are built, look at examples, and discuss the costs. Get ready to see the future of housing, one printed layer at a time.

What Are 3D Printed Houses?

At its core, 3D printing, also known as additive manufacturing, is the process of building a three-dimensional object from a computer-aided design (CAD) model. It works by joining materials, layer by layer, to create a solid object of almost any shape. While once just a concept studied in books, this technology is now a reality and quickly becoming more common.

When applied to construction, this means giant 3D printers create the home’s structural components. Instead of just a virtual 360-degree tour, you are getting a physical structure. This method is revolutionizing the construction process, making it faster and more precise. The technique of concrete printing has made it possible for home builders to create durable, complex home’s design structures that are both affordable and sustainable.

Benefits of 3D Printed Houses

Opting for 3D printed house designs is not just about cool technology; it comes with some serious advantages over traditional building.

- Speed: Homes can now be built in a matter of hours, with companies like COBOD demonstrating large-scale projects across regions of the US, such as Austin in Texas.

- Cost-Effective: The process can be much cheaper, with basic structures potentially costing as little as $4,000, depending on the design and square feet.

- Design Freedom: Slicer software suites allow immense design flexibility, letting you create open floor plans and organic shapes not possible with conventional methods.

- Efficiency: Automated printers use the precise amount of materials and energy, boosting energy efficiency and reducing waste.

- Durability: Advanced material mixes increase resilience, making homes suitable even for extreme climates or disaster-prone regions.

How Are 3D-Printed Houses Built?

It all starts with a digital blueprint. Engineers first design the house in a studio using specialized “slicer” software. This design is then translated into G-code, a programming language that the 3D printer understands. This code meticulously tracks the exact path and dimensions the printer must follow to create the 3D printed house designs.

A massive 3D printer, like the “Vulcan” (which has a 1-ton capacity), is brought to the building site. These printers often use lightweight aluminium frames for easy transport and movable tracks to roll into position. There is often no specific limit to the building’s height, allowing for diverse plans.

A special mortar mix, often a finely calibrated blend of cement, sand, and plasticizers is prepared. This mix is poured into a hopper and then extruded layer by layer from the printer’s nozzle, flowing onto the rising walls. This process creates thick, insulated walls, and the windows and doors are fitted afterward.

Image Credit: Pinterest

10 Examples of 3D Printed Houses

Here are 10 examples of 3D printed house designs you can consider for your future projects:

1. The Minimalist Micro-Home

This concept focuses on efficiency and affordability. Using 3D printing, a compact, single-person dwelling or “tiny house” can be constructed in just a day or two. These small house design ideas maximize every square inch, often featuring built-in furniture and smart, space-saving solutions. It represents a fast, low-cost answer to urban density and minimalist living.

Image Credit: Pinterest

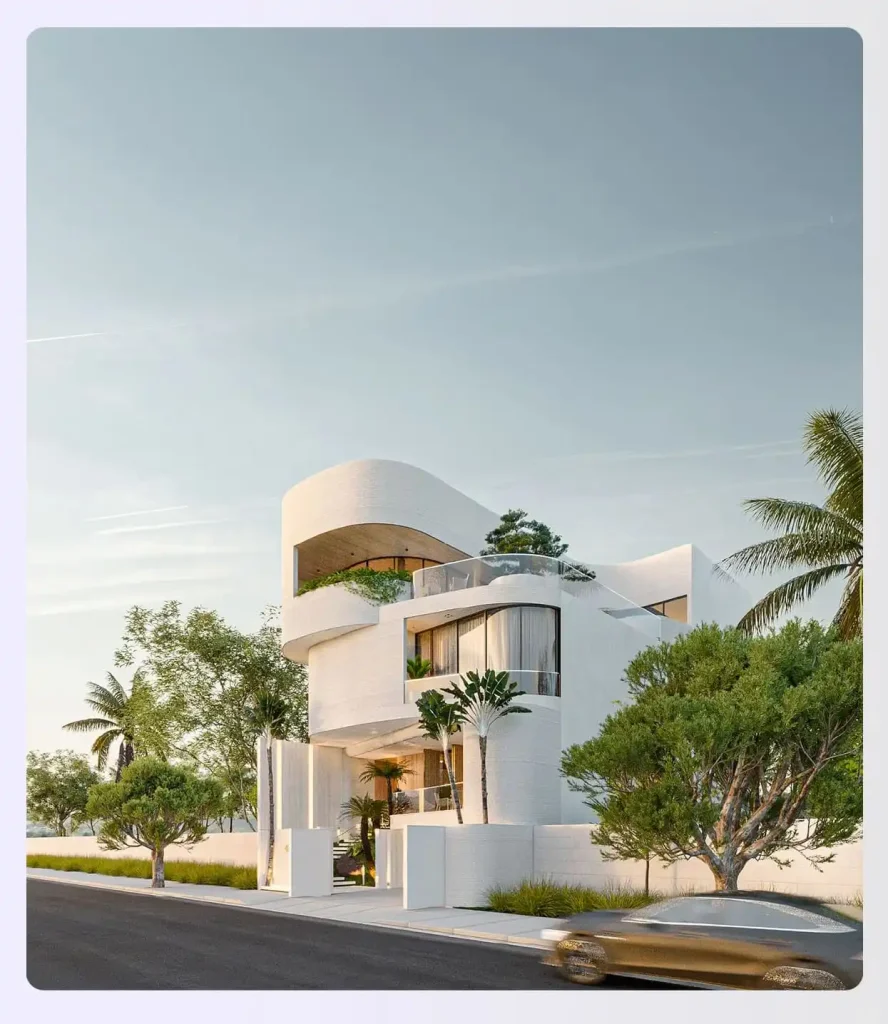

2. The Organic, Curvaceous Villa

This is where 3D printing truly shines. Forget straight lines and boxes; this design concept embraces organic, flowing, and biomimetic forms. The printer can create sweeping curves and rounded walls that mimic shapes found in nature. These contemporary interior design ideas are not only visually stunning but can also be more structurally efficient and create a unique, tranquil living environment.

Image Credit: Pinterest

3. The Eco-Friendly Earthen Home

This concept leverages 3D printing for ultimate sustainability. Instead of traditional concrete, the printer uses a mix of local, natural materials like soil, clay, and straw. The result is eco-friendly interior designs with an extremely low carbon footprint that blends perfectly into its natural surroundings. These 3D printed house designs offer excellent thermal insulation, creating a structure that is both eco-friendly and beautiful.

Image Credit: Pinterest

4. The Modular & Expandable Pod

Imagine a home that grows with your needs. This concept involves printing individual “pods” or modules—a bedroom, a kitchen, an office—that can be created off-site. These modules are then transported and seamlessly connected. This approach allows homeowners to start small and add new sections over time, offering incredible flexibility for changing family sizes or budgets.

Image Credit: Pinterest

5. The Two-Story Family Residence

This concept proves that 3D printing is not just for small-scale projects. Printers are now capable of constructing multi-level, two-story homes with footprints large enough for a whole family. These 3D printed house designs can look surprisingly conventional, integrating traditional elements like balconies and large windows, but are built with the speed and material efficiency of 3D printing.

Image Credit: Pinterest

6. The Luxury Biophilic Mansion

At the high end, 3D printing allows for unparalleled customization. This concept involves creating a luxury home designed around biophilic principles—a connection to nature. The printer can create massive, curved walls, integrated planters, and unique openings that maximize natural light and airflow. These 3D printed house designs merge high-tech construction with a deep, organic connection to the environment.

Image Credit: Pinterest

7. The Rapid-Response Disaster Shelter

This concept highlights the humanitarian potential of 3D printing. When a disaster strikes, these printers can be deployed to quickly build safe, durable shelters for displaced families. These structures can be printed in under 24 hours, are far more resilient than tents, and provide a dignified, secure place for people to begin rebuilding their lives.

Image Credit: Pinterest

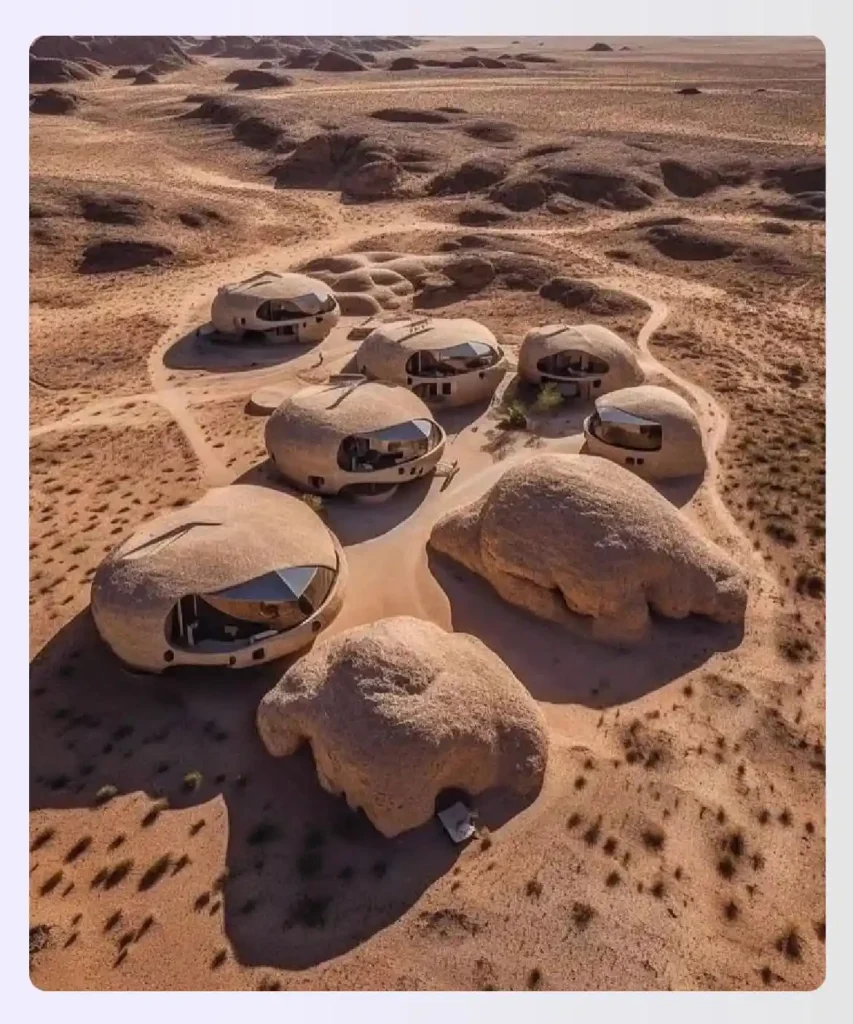

8. The Futuristic Off-Grid Habitat

This is a more conceptual, sci-fi-inspired idea. These 3D printed house designs are created for extreme or remote environments, like a desert, the arctic, or even as concepts for Mars. They are designed to be completely self-sufficient, with dome-like shapes to withstand high winds, integrated water-collection systems, and walls built from local materials.

Image Credit: Pinterest

9. The Affordable Housing Community

Beyond a single home, this concept uses 3D printing to tackle housing shortages at scale. A developer can print an entire community of modest, affordable homes quickly and at a reduced cost. By streamlining the construction of multiple units, this approach to 3D printed house designs can provide a viable, large-scale solution to the affordable housing crisis in many cities.

Image Credit: Pinterest

10. The Hybrid Construction Home

This is one of the most practical and popular concepts. It combines the best of both worlds: 3D printing is used to create the structurally complex and labor-intensive exterior and interior walls. Then, traditional construction methods are used to add the roof, windows, plumbing, and electrical. This hybrid model saves significant construction time and money on the home’s structure while retaining familiar finishes.

Image Credit: Pinterest

How Much Does 3D Printed House Cost?

The cost of 3D printed house designs can vary wildly. While some basic structures can cost as little as $4,000, this price only covers the printed walls. The final cost depends heavily on the size, complexity, location, and finishes.

- Base Structure: A small, basic home’s printed structure can be extremely cheap ($4,000 – $10,000), as it saves on labor and materials.

- Size and Complexity: Larger homes or complex, curved 3D printed house designs require more engineering and print time, increasing the price significantly.

- Finishing Costs: The $4,000 price does not include windows, doors, roofing, or plumbing. These finishes make up the bulk of the final cost, just like a traditional home.

- Land and Permits: You still need to buy the land and go through the local permitting process, which adds significant cost and varies by location.

- Printer Technology: The cost also depends on the company. As companies explore partnerships with groups like FEMA and Fannie Mae, prices may stabilize.

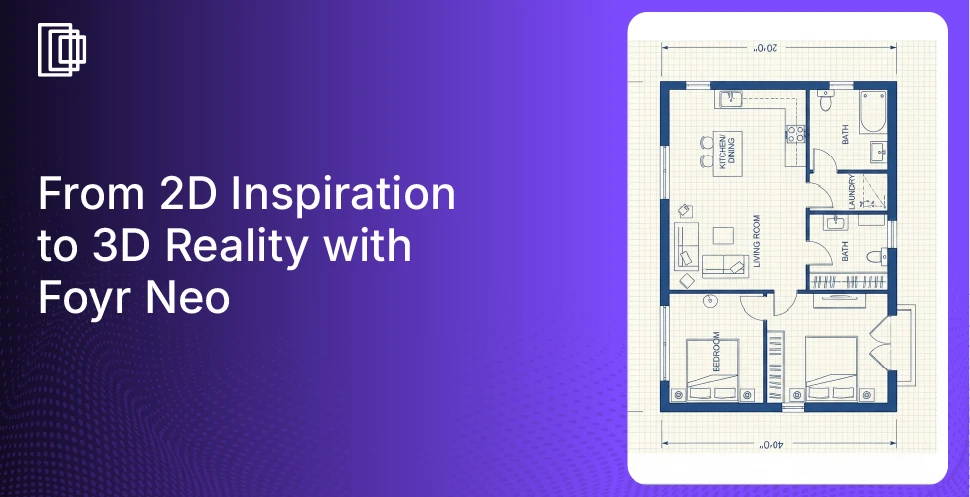

Design Your 3D Printed House with Foyr

Before you can print a house, you need a flawless digital blueprint. Visualizing complex 3D printed house designs can be challenging. That is where Foyr Neo comes in. It is the perfect interior design software for architects, designers, and even hobbyists to bring their futuristic ideas to life.

- Create detailed 2D and 3D floor plans in minutes.

- Drag and drop from a library of 60,000+ 3D models.

- Experiment with unique wall shapes, textures, and materials.

- Generate photorealistic 12K renders to visualize your design.

- Create virtual 360-degree tours, just like a virtual print.

Do not just imagine your dream home; see it. Foyr Neo’s powerful, lightning-fast software lets you iterate on your 3D printed house designs until every curve and corner is perfect. See your vision before it becomes concrete.

Start your 14-day free trial of Foyr Neo today!

FAQs

1. Are 3D printed houses legal?

Yes, but it is complicated. Legality depends on local building codes, which are still catching up to the technology. In many areas, 3D printed house designs must be approved on a case-by-case basis. However, as more companies build homes that meet international building standards, cities are beginning to create specific regulations for them.

2. What is the lifespan of a 3D printed house?

3D printed homes are built to last. Most are constructed using robust, concrete-based mortars that are as strong, or even stronger, than traditional concrete blocks. While the technology is new, engineers design these structures to have a lifespan of 50-100+ years, similar to conventional housing.

3. Can you get a mortgage for a 3D printed house?

This is one of the biggest hurdles. Lenders are often hesitant to finance new or “unconventional” construction methods. However, as 3D printed house designs become more common and are built by reputable companies that meet all building codes, more lenders and partners, like Fannie Mae, are beginning to explore financing options.

4. Can a 3D printed house withstand a tornado?

Yes, they are exceptionally strong. The layered, monolithic structure of a 3D printed concrete wall (without the joints of traditional block-work) is incredibly resilient. Many 3D printed house designs are specifically engineered to withstand extreme weather, including high winds and hurricanes, making them a very safe housing option.

5. How do you insulate a 3D printed house?

Insulation is integrated directly into the printing process. As the printer builds the walls, it often creates two separate layers with a gap in between. This cavity is then filled with an insulating material, like polyurethane foam, or the concrete mix itself has insulating properties. This creates a thick, highly energy-efficient wall.